Xyz-gz integrated thin oil station (0.4MPa)

本产品适用于冶金、矿山、建材、能源、交通等行业中机械设备的稀油润滑,工作介质为粘度等级N22~N460(相当于IS0 VG22~460)的工业润滑油。

Gdko3 type electric control box has two types: monitoring and full-automatic. It is applicable to the 40MPa double line terminal dry oil centralized lubrication system. It is used to control the coordinated work of the lubrication pump, reversing valve, grease replenishing pump, etc. it can automatically supply oil to the oil supply points in the system. After the oil supply is completed, it will automatically stop. When the liquid level in the oil tank is lower than a certain limit, the grease replenishing pump will start automatically and stop automatically after filling with oil.

Key Word:

Electric control box | tyre repair pump | hydraulic equipment

Category:

Thin oil lubrication device and thin oil station

Thin oil lubrication part

Product Description

1、 Overview

Gdko3 type electric control box has two types: monitoring and full-automatic. It is applicable to the 40MPa double line terminal dry oil centralized lubrication system. It is used to control the coordinated work of the lubrication pump, reversing valve, grease replenishing pump, etc. it can automatically supply oil to the oil supply points in the system. After the oil supply is completed, it will automatically stop. When the liquid level in the oil tank is lower than a certain limit, the grease replenishing pump will start automatically and stop automatically after filling with oil.

This control box can send out fault signals such as "extended oil supply time", "empty oil reservoir", "overload operation", etc. It has continuous, manual and automatic control working states, which can be switched through the change-over switch on the box surface. Continuous working state: when the lubricating pump is started, it continuously supplies lubricating grease to the two main lines of the system; Manual working state: when the interlocking signal with the main engine is connected, the lubricating pump is manually started to feed the lubricating grease to the steering system, and the automatic reversing is automatically stopped after one lubrication cycle is completed; Automatic working state: when the interlocking signal with the main engine is connected, the lubricating pump will supply lubricating grease to the system at regular intervals according to the time interval set by the system, and it will automatically stop after completing a lubrication cycle. No matter what state the lubricating pump is in, once the oil reservoir is empty, the grease replenishing pump will automatically start to replenish grease and stop automatically after replenishing.

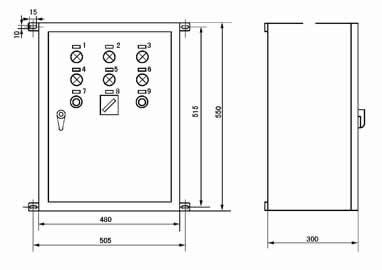

2、 Overall dimensions

3、 Sign symbols and words

| Serial number |

Symbol

|

Nameplate text

|

Serial number

|

Symbol

|

Nameplate text

|

Serial number

|

Symbol

|

Nameplate text

|

|

1

|

HL1

|

Work preparation instructions

|

6

|

HL6

|

System overpressure

|

11

|

SB4

|

Refueling pump start

|

|

2

|

HL2

|

Working state of line I

|

7

|

HL7

|

Pump motor overload

|

12

|

SB5

|

Refueling pump stop

|

|

3

|

HL3

|

Working state of line II

|

8

|

HL8

|

Oil reservoir empty

|

13

|

SB3

|

Fault reset

|

|

4

|

HL4

|

Refueling pump operation

|

9

|

SB1

|

Lubrication pump start

|

14

|

SA1

|

Automatic / manual / continuous

|

|

5

|

HL5

|

Monitoring time exceeds

|

10

|

SB2

|

Lubrication pump stop

|

15

|

SA2

|

Off / bell / on

|

| 一、使用条件 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 本产品适用于冶金、矿山、建材、能源、交通等行业中机械设备的稀油润滑,工作介质为粘度等级N22~N460(相当于IS0 VG22~460)的工业润滑油。 整体式稀油站的特点为全部零部件均布置在油箱上,性能参数基本上和XYZ-G型相同,但将流量大于125L/min的五种规格稀油站亦制成整体式,因而这些较大的油站仍可实现整体吊装,无地脚螺栓,使安装特别方便;特别适合于稀油占地面积受到限制的场合;但稀油站上面和四周需留足够的维修高度和面积; 由于油泵在油箱顶上,因此选用的油泵应有足够的吸入高度,特别当润滑油粘度高,油温低时更要引起重视。 整体式稀油站的供油压力≤0.4MPa,过滤精度0.08~0.12mm(低粘度时允许采用小值),冷却水温度≤30℃,压力为0.2~0.4MPa,冷却器进油温度为50℃,通过冷却器后温降≥8℃;采用电加热器提高油温。 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 二、工作原理 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 与XYZ-G 型≤125L/min的稀油站相同,亦采用电加热器提高油温。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 三、结构特点 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 亦与XYZ-G型≤125L/min的稀油站相同,但采用磁网一体化进行回油过滤后,均取消了外加的磁过滤器;仪表盘(板)亦与XYZ-6G~125G相同。 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 四、技术参数 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

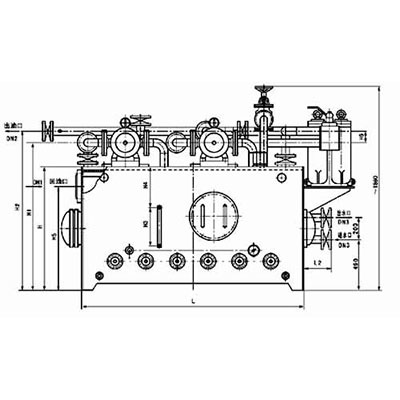

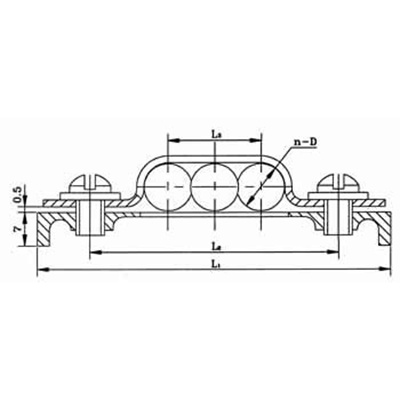

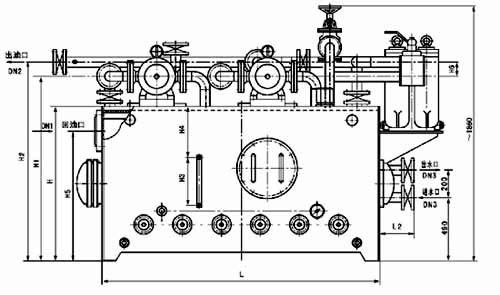

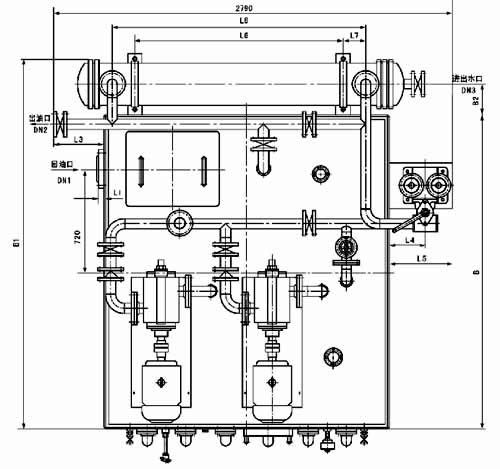

| 五、外形尺寸 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| XYZ-GZ 型稀油站外形尺寸 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

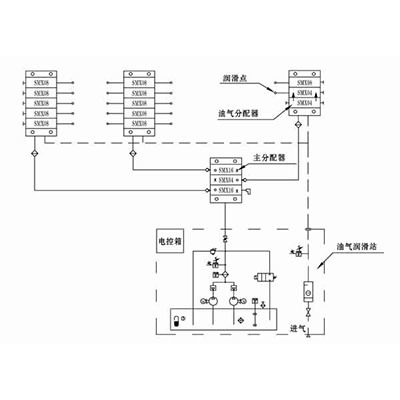

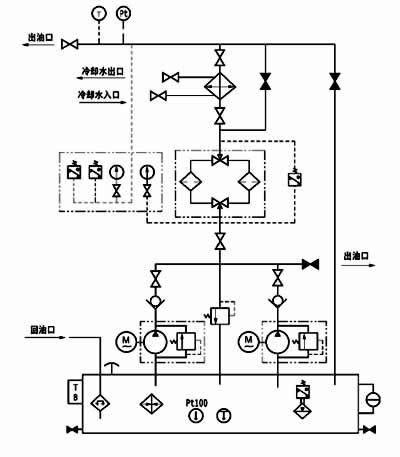

| 六、原理图 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

图1-3-2 XYZ-GZ 型稀油站原理图

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

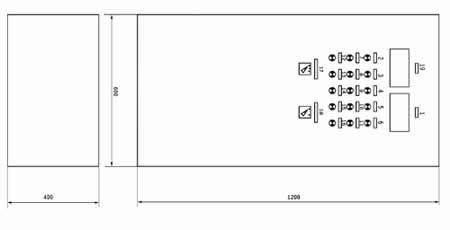

| 七、仪表盘 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 和XYZ-6G~125G型稀油站的仪表盘(板)相同 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

图1-3-3 XYZ-GZ型稀油站电控外形图 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RELATED PRODUCTS

CONSULTING PRODUCTS