Gdk03 electric control box (40MPa)

GDKO3型电控箱有监控及全自动两种,它适用于40MPa双线终端式干油集中润滑系统中,用于控制润滑泵、换向阀、补脂泵等相互间协调工作,能对系统中的供油点实现自动供油,供油完成后,自动停止。油箱中液位低于一定限度时,补脂泵自动启动,注满油后,自动停止。

Gdko3 type electric control box has two types: monitoring and full-automatic. It is applicable to the 40MPa double line terminal dry oil centralized lubrication system. It is used to control the coordinated work of the lubrication pump, reversing valve, grease replenishing pump, etc. it can automatically supply oil to the oil supply points in the system. After the oil supply is completed, it will automatically stop. When the liquid level in the oil tank is lower than a certain limit, the grease replenishing pump will start automatically and stop automatically after filling with oil.

Key Word:

Electric control box | tyre repair pump | hydraulic equipment

Category:

Electrical control part

Product Description

1、 Overview

Gdko3 type electric control box has two types: monitoring and full-automatic. It is applicable to the 40MPa double line terminal dry oil centralized lubrication system. It is used to control the coordinated work of the lubrication pump, reversing valve, grease replenishing pump, etc. it can automatically supply oil to the oil supply points in the system. After the oil supply is completed, it will automatically stop. When the liquid level in the oil tank is lower than a certain limit, the grease replenishing pump will start automatically and stop automatically after filling with oil.

This control box can send out fault signals such as "extended oil supply time", "empty oil reservoir", "overload operation", etc. It has continuous, manual and automatic control working states, which can be switched through the change-over switch on the box surface. Continuous working state: when the lubricating pump is started, it continuously supplies lubricating grease to the two main lines of the system; Manual working state: when the interlocking signal with the main engine is connected, the lubricating pump is manually started to feed the lubricating grease to the steering system, and the automatic reversing is automatically stopped after one lubrication cycle is completed; Automatic working state: when the interlocking signal with the main engine is connected, the lubricating pump will supply lubricating grease to the system at regular intervals according to the time interval set by the system, and it will automatically stop after completing a lubrication cycle. No matter what state the lubricating pump is in, once the oil reservoir is empty, the grease replenishing pump will automatically start to replenish grease and stop automatically after replenishing.

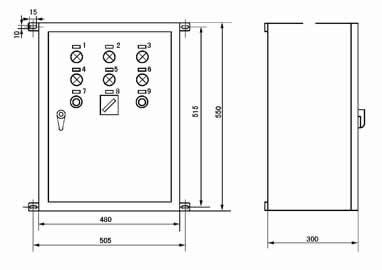

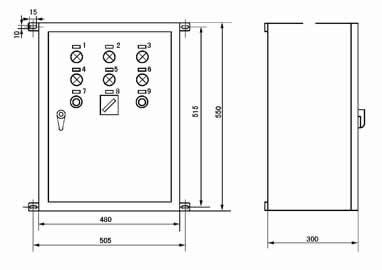

2、 Overall dimensions

3、 Sign symbols and words

| Serial number |

Symbol

|

Nameplate text

|

Serial number

|

Symbol

|

Nameplate text

|

Serial number

|

Symbol

|

Nameplate text

|

|

1

|

HL1

|

Work preparation instructions

|

6

|

HL6

|

System overpressure

|

11

|

SB4

|

Refueling pump start

|

|

2

|

HL2

|

Working state of line I

|

7

|

HL7

|

Pump motor overload

|

12

|

SB5

|

Refueling pump stop

|

|

3

|

HL3

|

Working state of line II

|

8

|

HL8

|

Oil reservoir empty

|

13

|

SB3

|

Fault reset

|

|

4

|

HL4

|

Refueling pump operation

|

9

|

SB1

|

Lubrication pump start

|

14

|

SA1

|

Automatic / manual / continuous

|

|

5

|

HL5

|

Monitoring time exceeds

|

10

|

SB2

|

Lubrication pump stop

|

15

|

SA2

|

Off / bell / on

|

一、概述

GDKO3型电控箱有监控及全自动两种,它适用于40MPa双线终端式干油集中润滑系统中,用于控制润滑泵、换向阀、补脂泵等相互间协调工作,能对系统中的供油点实现自动供油,供油完成后,自动停止。油箱中液位低于一定限度时,补脂泵自动启动,注满油后,自动停止。

本控制箱能发出“供油时间延长”、“贮油筒空”、“超负荷运转”等故障信号。具有持续,手动和自动多种控制工作状态,可通过箱面上的转换开关来切换。持续工作状态:当润滑泵启动后持续地向系统两条主管线供送润滑脂;手动工作状态:当与主机联锁信号接通后,手动启动润滑泵运转向系统供送润滑脂,自动换向完成一个润滑周期供脂后自动停止;自动工作状态:当与主机联锁信号接通后,润滑泵按系统设定的时间间隔定时向系统供送润滑脂,完成一个润滑周期后自动停止。润滑泵不管在何种状态,一旦贮油筒空,补脂泵就会自动启动补脂,补满后自动停止。

二、外形尺寸

三、标牌符号及文字

|

序号

|

符号

|

标牌文字

|

序号

|

符号

|

标牌文字

|

序号

|

符号

|

标牌文字

|

|

1

|

HL1

|

工作准备指示

|

6

|

HL6

|

系统超压

|

11

|

SB4

|

加油泵启动

|

|

2

|

HL2

|

线I工作状态

|

7

|

HL7

|

泵马达过载

|

12

|

SB5

|

加油泵停止

|

|

3

|

HL3

|

线II工作状态

|

8

|

HL8

|

贮油筒空

|

13

|

SB3

|

故障复位

|

|

4

|

HL4

|

加油泵工作

|

9

|

SB1

|

润滑泵启动

|

14

|

SA1

|

自动/手动/持续

|

|

5

|

HL5

|

监控时间超过

|

10

|

SB2

|

润滑泵停止

|

15

|

SA2

|

关/电铃/开

|

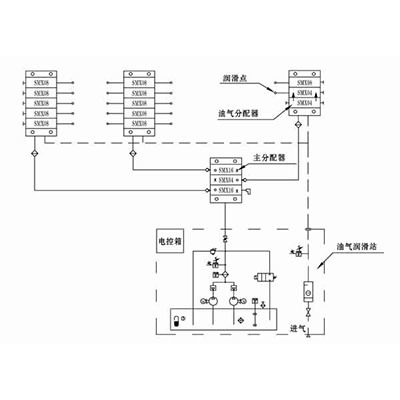

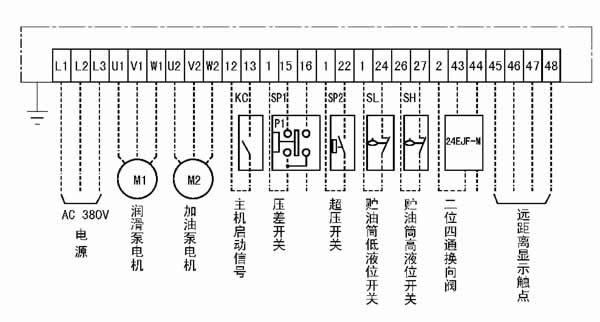

四、GDK-03电气控制箱外部接线图

五、使用说明

1、适用主电源AC380V、50HZ。

2、适用环境温度-10℃~40℃,湿度90%。

3、周围环境无导电的介质(气体、液体)。

4、垂直安装,其倾斜度不大于5°。

RELATED PRODUCTS

CONSULTING PRODUCTS